Here is a great article from the UL website in regards to UL and C-UL Classifications for Hazardous Locations, that is helpful.

Read the full article on UL’s site here: UL and C-UL Classifications, Hazardous, NA (UL.COM Hazardous-Locations)

Source: www.ul.com

Author: UL, LLC.

UL and C-UL Certification for North America

UL and C-UL Classifications for Hazardous Locations

Gain a better understanding of the definition of a Hazardous Location and area classification as well as the UL and C-UL Certification for North America.

What is a Hazardous Location?

Location where explosion or fire hazards exist due to the presence of flammable gases, flammable or combustible liquid-produced vapors, combustible dusts, or ignitable fibers or flyings.

How are UL Hazardous Areas Classified?

Area Classification – Hazardous Locations are classified by the likelihood of an ignitable concentration of combustible material being present. There are two systems in place, including the traditional North American Division system as well as the alternative Zone system. See below for further details:

DIVISION SYSTEM (NEC ARTICLE 500 THROUGH 503/CEC SECTION 18)

Sample Marking:

- Divisions

- Division 1 – Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produces vapors can exist under normal operating conditions.

- Division 2 – Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produces vapors are not likely to exist under normal operating conditions.

- Class – Materials are divided by type:

- Class I – Flammable gases, flammable liquid produced vapors, and combustible liquid produced vapors

- Class II – Combustible dusts

- Class III – Ignitable fibers / flyings

- Groups – Materials are further divided into Groups for Class I, Divisions 1 and 2:

- A – Acetylene

- B – Hydrogen

- C – Ethylene

- D – Propane

- Groups – Materials are further divided into Groups for Class II, Division 1 and 2:

- E – Metal Dusts (Div. 1 only)

- F – Carbonaceous Dusts

- G – Non-Conductive Dusts (flour, grain, wood, plastic, etc.)

What is the difference between a Class I, Division 1 Location and Class I, Division 2 Location? What about the differences between the other locations?

UL Class I, Division 1 Location

- Ignitable concentrations of flammable gases, vapors or liquids:

- can exist under normal operating conditions;

- may exist frequently because of repair or maintenance operations or leakage; or

- may exist because of equipment breakdown that simultaneously causes the equipment to become a source of release.

UL Class I, Division 2 Location

- Volatile flammable liquids or flammable gases or vapors exist, but are normally confined within closed containers;

- Ignitable concentrations of gases, vapors or liquids are normally prevented by positive mechanical ventilation; or

- Adjacent to a Class I, Division 1 location where ignitable concentrations might be occasionally communicated.

Class II, Division 1 Location

- Ignitable concentrations of combustible dust can exist in the air under normal operating conditions;

- Ignitable concentrations of combustible dust may exist because of equipment breakdown that simultaneously causes the equipment to become a source of ignition; or

- Electrically conductive combustible dusts may be present in hazardous quantities.

Class II, Division 2 Location

- Combustible dust is not normally in the air in ignitable concentrations;

- Dust accumulations are normally insufficient to interfere with normal operation of electrical equipment;

- Dust may be in suspension in the air as the result of infrequent malfunction of equipment; or

- Dust accumulation may be sufficient to interfere with safe dissipation of heat or may be ignitable by abnormal operation.

Class III, Division 1 Location

- A location in which easily ignitable fibers or materials producing combustible flyings are handled, manufactured or used.

Class III, Division 2 Location

- A location in which easily ignitable fibers are stored, or handled other than in the process of manufacture.

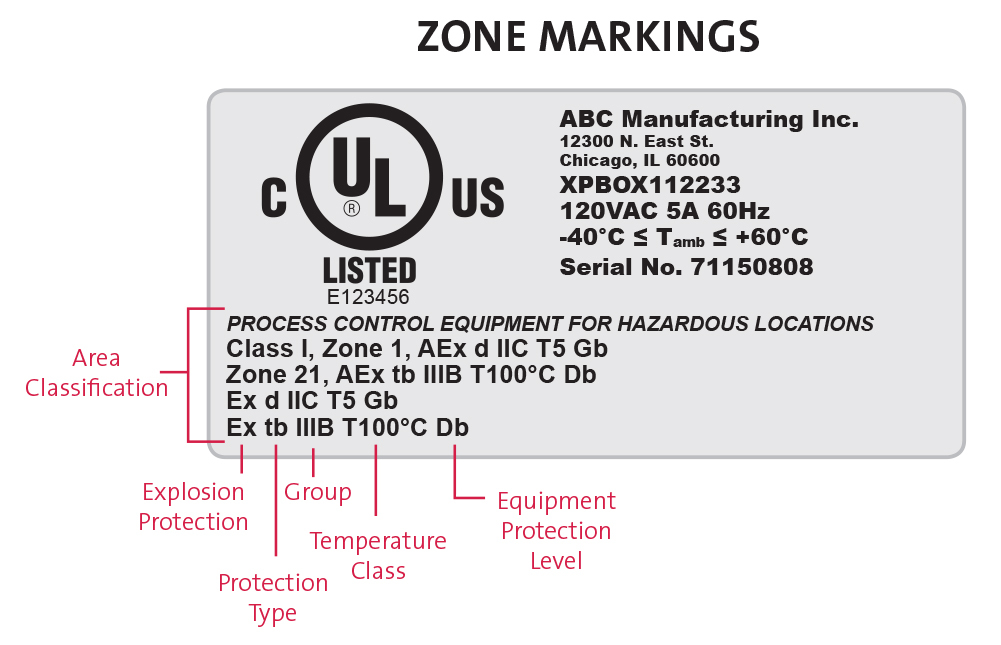

UL ZONE SYSTEM (NEC ARTICLE 505-506 / CEC SECTION 18)

Sample Marking:

- UL Zones

- Zone 0 – Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produces vapors are present continuously or for long periods of time under normal operating conditions.

- Zone 1 – Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produces vapors are likely to exist under normal operating conditions.

- Zone 2 – Ignitable concentrations of flammable gases, flammable liquid-produced vapors, or combustible liquid-produces vapors are not likely to exist under normal operating conditions.

- Zone 20 – Ignitable concentrations of combustible dust or ignitable fibers/flyings are present continuously or for long periods of time under normal operating conditions.

- Zone 21 – Ignitable concentrations of combustible dust or ignitable fibers/flyings are likely to exist occasionally under normal operating conditions.

- Zone 22 – Ignitable concentrations of combustible dust or ignitable fibers/flyings are not likely to occur under normal operating conditions.

- Groups – Class I, Zone 0, 1, and 2

- IIC – Acetylene & Hydrogen

- IIB + H2 – Hydrogen

- IIB – Ethylene

- IIA – Propane

- Groups – Zone 20, 21, and 22

- IIIC – Conductive Dust

- IIIB – Non-Conductive Dust

- IIIA – Combustible Flyings

- Electrical Protection Types – Gas Atmospheres

- “d” – flameproof (for EPL Gb or Mb)

- “e” – increased safety (for EPL Gb or Mb)

- “ia” – intrinsic safety (for EPL Ga or Ma)

- “ib” – intrinsic safety (for EPL Gb or Mb)

- “ic” – intrinsic safety (for EPL Gc)

- “ma” – encapsulation (for EPL Ga or Ma)

- “mb” – encapsulation (for EPL Gb or Mb)

- “mc” – encapsulation (for EPL Gc)

- “nA” – non-sparking (for EPL Gc)

- “nC” – protected sparking (for EPL Gc)

- “nR” – restricted breathing (for EPL Gc)

- “o” – oil immersion (for EPL Gb)

- “op is” – inherently safe optical radiation (for EPL Ga, Gb or Gc)

- “op pr” – protected optical radiation (for EPL Gb or Gc)

- “op sh” – optical system with interlock (for EPL Ga, Gb or Gc)

- “pv” – pressurization (for EPL Gb or Gc)

- “px” – pressurization (for EPL Gb or Mb)

- “py” – pressurization (for EPL Gb)

- “pz” – pressurization (for EPL Gc)

- “q” – powder filling (for EPL Gb or Mb)

- Electrical Protection Types – Dust Atmospheres

- “ta” – protection by enclosure (for EPL Da)

- “tb” – protection by enclosure (for EPL Db)

- “tc” – protection by enclosure (for EPL Dc)

- “ia” – intrinsic safety (for EPL Da)

- “ib” – intrinsic safety (for EPL Db)

- “ma” – encapsulation (for EPL Da)

- “mb” – encapsulation (for EPL Db)

- “mc” – encapsulation (for EPL Dc)

- “p” – pressurization (for EPL Db or Dc)

- Equipment Protection Level (EPL) – Level of protection assigned to equipment based on its likelihood of becoming a source of ignition and distinguishing the differences between explosive gas atmospheres, explosive dust atmospheres, and the explosive atmospheres in mines susceptible to fire damp.

- EPL Ma – Equipment for installation in a mine susceptible to firedamp, having a very high level of protection, which has sufficient security that it is unlikely to become an ignition source in normal operation, during expected malfunctions or during rare malfunctions, even when left energized in the presence of an outbreak of gas.

- EPL Mb – Equipment for installation in a mine susceptible to firedamp, having a high level of protection, which has sufficient security that it is unlikely to become a source of ignition in normal operation or during expected malfunctions in the time span between there being an outbreak of gas and the equipment being de-energized.

- EPL Ga – Equipment for explosive gas atmospheres, having a very high level of protection, which is not a source of ignition in normal operation, during expected malfunctions or during rare malfunctions.

- EPL Gb – Equipment for explosive gas atmospheres, having a high level of protection, which is not a source of ignition in normal operation or during expected malfunctions.

- EPL Gc – Equipment for explosive gas atmospheres, having an enhanced level of protection, which is not a source of ignition in normal operation and which may have some additional protection to ensure that it remains inactive as an ignition source in the case of regular expected occurrences (for example failure of a lamp).

- EPL Da – Equipment for explosive dust atmospheres, having a very high level of protection, which is not a source of ignition in normal operation, during expected malfunctions, or during rare malfunctions.

- EPL Db – Equipment for explosive dust atmospheres, having a high level of protection, which is not a source of ignition in normal operation or during expected malfunctions.

- EPL Dc – Equipment for explosive dust atmospheres, having an enhanced level of protection, which is not a source of ignition in normal operation and which may have some additional protection to ensure that it remains inactive as an ignition source in the case of regular expected occurrences (for example failure of a lamp).

*Article from UL Website / UL and C-UL Classifications for Hazardous Locations

For more information or to get a quotation, please contact us:

Ph. 877-880-7728

Email: info@ellipsesecurity.com

Planning a CCTV installation in a hazardous environment requires careful planning and attention to the different Division and Zone classifications. Classifications are derived from a number of factors and systems as described above. If you are needing assistance with your application, we can help. Ellipse Security is a Authorized Distributor for VideoTec Products as well as Hanwha Techwin Products. Both VideoTec and Hanwha offer a variety of options for Explosion Proof Cameras, Explosion Proof Housings, Stainless Steel Cameras, PTZ’s, Housings and More!

Explosion Proof Cameras and Housings

Stainless Steel Security Cameras